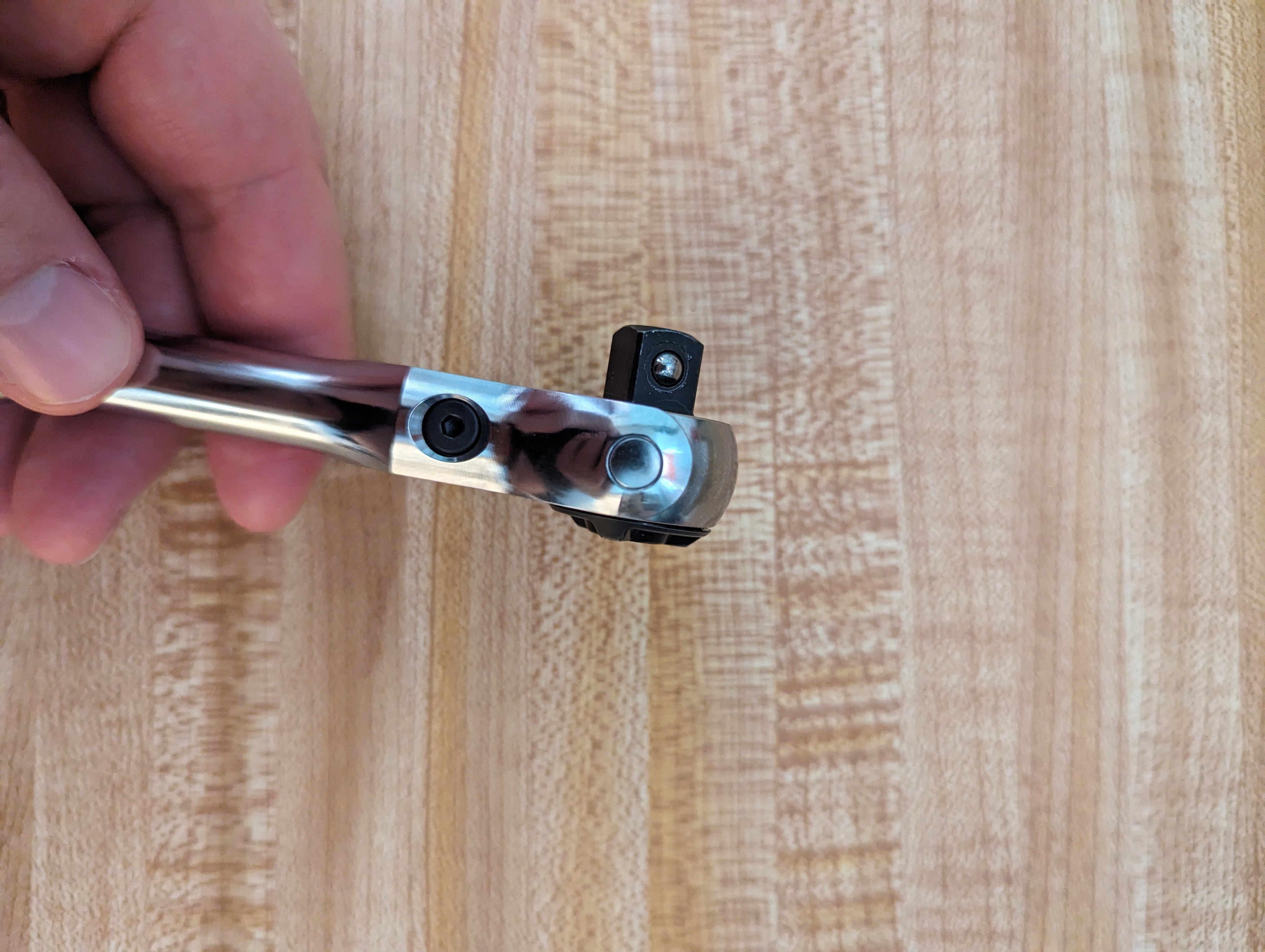

Is this a specialized socket wrench? What are we looking at here? (Trying to provide context for others who might be sorting by new)

Tools

Tools of all sorts are welcome. They include hand tools, power tools, automotive tools, welding, etc...

Both just Roto-Head ratchets. Bottom one (KTC) is just a standard Roto-Head ratchet. Top one (TONE) is a little bit gimmicky, aluminum handle, offset pawl designs 72x2 teeth, and locking head (that's what the wheel in the middle is for).

Neither sold outside of Japan afaik. So I thought I'd share.

Very nice! Thank you for the clarification 😄

Nice Sonic Screwdrivers

Wouldn't pay a single penny for a ratchet handle with a split down the shaft like that.

Looks like gimmicky crap to me

- This style of ratchet has been around for about 100 years, not really a gimmick.

- They're built for accessibility not strength. The swivel head helps reach bolts in hard to reach places.

- The weak point on these ratchets and all style of ratchets in general will be the teeth on the pawls or the drive itself. Both are replaceable.

The one at the bottom; I can't see single reason why it needs a split shaft

The head swivels around.

That's still no reason for there to be a gap, all the way down the shaft to the handle. That's just a potential weakness

Do you actually use tools professionally or just collect them, btw?

If the latter, then yeah that's pretty cool!

The pivot point is part of the head itself so I think you need the gap to connect the head to the handle in the first place. Or no gap and hold the head in with 2 screws. Most professional brands (Snap-On, Mac, Matco) use the same gap design though. Not a professional myself, just adding to my collection lol.